Nature appreciates - no environmental impact.

- smart graywater cleaner -

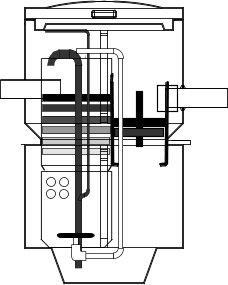

Six-step cleaning process:

1) precipitation treatment - pre-treatment

2) fat separation - pretreatment

3) microbiological purification - bioprocess

4) aeration - bioprocess

5) water recycling - bioprocess

6) effluent filtration - after - treatment

Enhanced natural method

Pretreatment

In the pre-treatment (tank 1), solids and grease are separated from the wastewater entering the treatment plant by gravity. The bioprocess begins under anaerobic (anaerobic) conditionsBioprocess

The bioprocess is based on the efficient biofiltration of gray wastewater. The microbes are in the biofilter and in the water which is circulated by an air lift pump (no moving parts) under aerobic (oxygen) conditions through the filter. The bioprocess is highly resistant to load fluctuations and reacts quickly to changes in water volume and load. Organic loads and nutrients are broken down by biological microbial activity (biofilm). Microbial activity takes place in the filter elements. There are three different densities of elements (290, 350, 450 m2 / m3). They make the biofiltration (biofilm) process, which is common in nature, more efficient in a small space. The microbes in the elements remove organic matter, nutrients biologically. Thanks to the large surface area of the elements and good air circulation, cleaning is very efficient. The RAITA HS treatment plant works well in areas with load fluctuations, the enhanced filter reacts quickly to changes in load. Purified water can be discharged into a ditch, rock pit or filtered into the ground.Cleaning performance

The cleaning performance and technical properties comply with EU standards - see the RAITA HS Declaration of Conformity (“declaration of conformity” use and installation instructions in the link) regarding cleaning performance and technical features of the device. The cleaning efficiency of the HS treatment plant has been tested, see link (HS Bio cleaning performance) .Maintenance

The microbial cleaning filter element is lifted and cleaned if necessary (once every 3-4 years) by brushing or washing. The post-filtration element is cleaned if necessary (for example during sludge emptying). The waste to be cleaned from the elements is composted or delivered to waste disposal. The sludge from the settling well is removed once a year with a SAV trolley or tank truck. The rubber diaphragms of the air pump are replaced every 4-5 years.Operating costs

Very low operating costs, filters are replaced every 10 years, electricity consumption ~ 60 w / m3 water cleaned.Bio HS's process utilizes

natural bio-cleaning

Gray water treatment