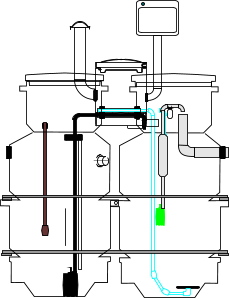

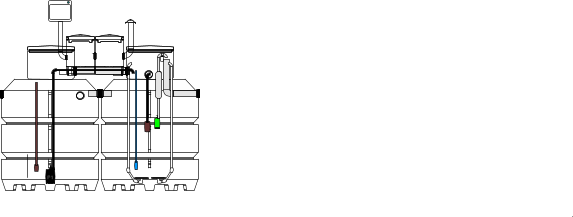

Efficient cleaning process:

In the process tank, bioprocesses; aeration of organic material, nitrification, denitrification takes place one after the other. In addition to bioprocesses, a chemical process works simultaneously .Bioprocess:

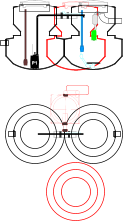

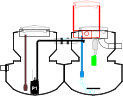

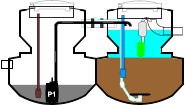

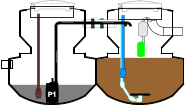

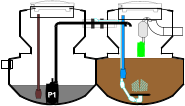

All wastewater from the property is led to a treatment plant. The first tank space is the pre-treatment space for wastewater. The treatment plant monitors incoming wastewater volumes and automatically adjusts the treatment plant's functions when the load changes. When enough water has accumulated in the pre- treatment tank, aeration of the organic material in the wastewater and nitrogen nitrification (fine bubble aeration) begin. During aeration, an air pump is used to pump air through pipelines to a fine bubble spreader. During aeration, the active sludge in the process tank is mixed with the pretreated wastewater, whereby the bioprocess begins, whereby the microbial growth in the active sludge uses organic material as food. At the same time, nitrification takes place, whereby the nitrogen changes state. The air that is pumped out into the water leaves the treatment plant through drainage ventilation on the roof of a residential building.Chemprocess:

While aeration is in progress, RAKE iron chemical is metered into the treatment plant to separate phosphorus. At the end of the aeration, a clarification period begins, during which the activated sludge and phosphorus (reacted with the iron chemical) precipitate to the bottom of the process tank.Clarification:

At the end of the process, the water treated with BioKem processes is clarified. At the same time, the last of the bioprocesses takes place, denitrification.Pumping of purified water:

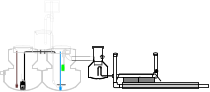

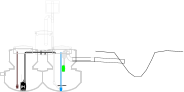

At the end of the clarification period, the clarified water, ie purified water, is pumped out of the treatment plant using a P2 pump. The clarifier is pumped through the pipes, whereby a part of the purified water is automatically separated in a monitoring vessel with a tap placed in the pipes. It is easy to determine the efficiency of the treatment plant operation from the monitoring test.Automatic functions in case of downtime:

The treatment plant is equipped with automatic functions to maintain biological readiness during times without incoming wastewater (downtime). The treatment plant automatically supplies air and wastewater to the process tank when the downtime continues. Thanks to the automatic functions the downtime can be about 3 months without special measures.Purified water is led to nature:

Purified water can be led directly to an open ditch or absorbed / filtered by simple post-filtration in the terrain. The degree of purification is sufficient even for sensitive areas (beaches and groundwater areas) Further treatment, ie the so-called third stage (eg particularly sensitive beach areas, groundwater areas) can also be connected to the treatment plant, which ensures even higher treatment and hygiene of the outgoing water with UV light.Sludge treatment:

The sludge to be removed from the treatment plant is odorless and stabilized in the bioprocesses. It is generated in small amounts, 0.3 to 0.1% of the amount of purified wastewater (1-3 l / m3). The sludge treatment equipment is connected to the treatment plant to remove excess sludge from the process tank. The sludge is removed to a separate sludge tank, from where it is emptied by a tanker for municipal treatment. The tank size is dimensioned for emptying intervals once a year. The sludge can also be taken to a composter connected to the treatment plant, in which case no emptying of the tanker is required.RAITA BioKem utilizes

natural biochemical

cleaning

Asennus- ja käyttöohjeet biomoduulit

CE

EN 12566-3

RAITA BIOKEM processes: